TECHNICAL INFO

Technical Bulletin:

Performance Test Results of Brake Calipers Against Corrosion

This bulletin details the performance of two car brake calipers exposed to corrosion testing through the Galvanized Salt Spray Performance Test (Test 1) and the Geomet Salt Spray Performance Test (Test 2).

Test 1 – Galvanized Salt Spray Performance:

In this test, the requirements included no white corrosion for the first 144 hours and no red rust for 168 hours. Results indicated excellent initial performance, with no corrosion observed up to 168 hours, followed by white corrosion at 192 hours, and red corrosion at 216 hours. However, a significant reduction in corrosion resistance was observed at 696 hours.

Test 2 – Geomet Salt Spray Performance:

Conversely, in this test, under stringent conditions (5% salt solution, pH 6.5-7.2, 35°C ambient temperature, 47°C pressure chamber, 85% RH, and 1.0 MPa air pressure), the other caliper demonstrated robust corrosion resistance as it exhibited no signs of rust throughout the entire test duration of 696 hours.

Conclusion:

This significant difference in performance underscores the superior protective capabilities of the Geomet treatment against corrosion compared to the galvanized finish, with Test 2 confirming that the caliper displayed remarkable durability in corrosive environments.

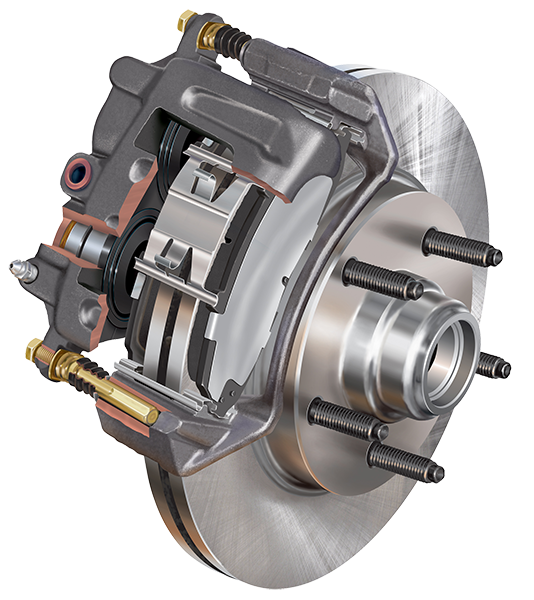

A car brake caliper is a crucial component in the braking system, as it houses the brake pads and pistons that are responsible for slowing down and stopping the vehicle. When the brake pedal is pressed, hydraulic pressure is exerted on the caliper, causing the piston to squeeze the brake pads against the rotor, generating friction and ultimately stopping the vehicle. The caliper must be functioning properly to ensure efficient and safe braking performance, making it essential for overall vehicle safety. Regular maintenance and inspection of the calipers are vital to ensure optimal braking efficiency and prevent potential brake system failures.

Here are 10 technical tips for installing a car brake caliper:

- Always start by loosening the lug nuts before raising the car.

- Clean the caliper mounting bracket thoroughly before installing the new caliper.

- Use a brake cleaner to remove any debris or brake fluid from the area.

- Properly lubricate the slide pins and bolts to ensure smooth operation.

- Double-check the brake pads for wear and replace them if necessary.

- Bleed the brake system after installing the caliper to remove any air bubbles.

- Torque all bolts to the manufacturer’s specifications to prevent caliper misalignment.

- Inspect the brake lines for any leaks or damage while working on the caliper.

- Consider replacing the brake fluid if it is old or contaminated.

- Test the brakes thoroughly before driving the car to ensure proper functionality.

Symptoms of a faulty car brake caliper include:

- Uneven braking

- Leaking brake fluid

- Pulling to one side when braking

- Overheating brakes

- Squeaking or grinding noises when braking

- Vibrations when applying the brakes

- Excessive brake pedal travel

- Reduced braking power

- Illuminated brake warning light on the dashboard

- Visible wear or damage on the caliper itself

These issues can compromise the safety and effectiveness of your braking system and should be addressed promptly by a qualified mechanic.

Talk to us

Have any questions? We are always open to talk about your business, new projects, new opportunities and how we can help you.