DIY GUIDE

Introduction

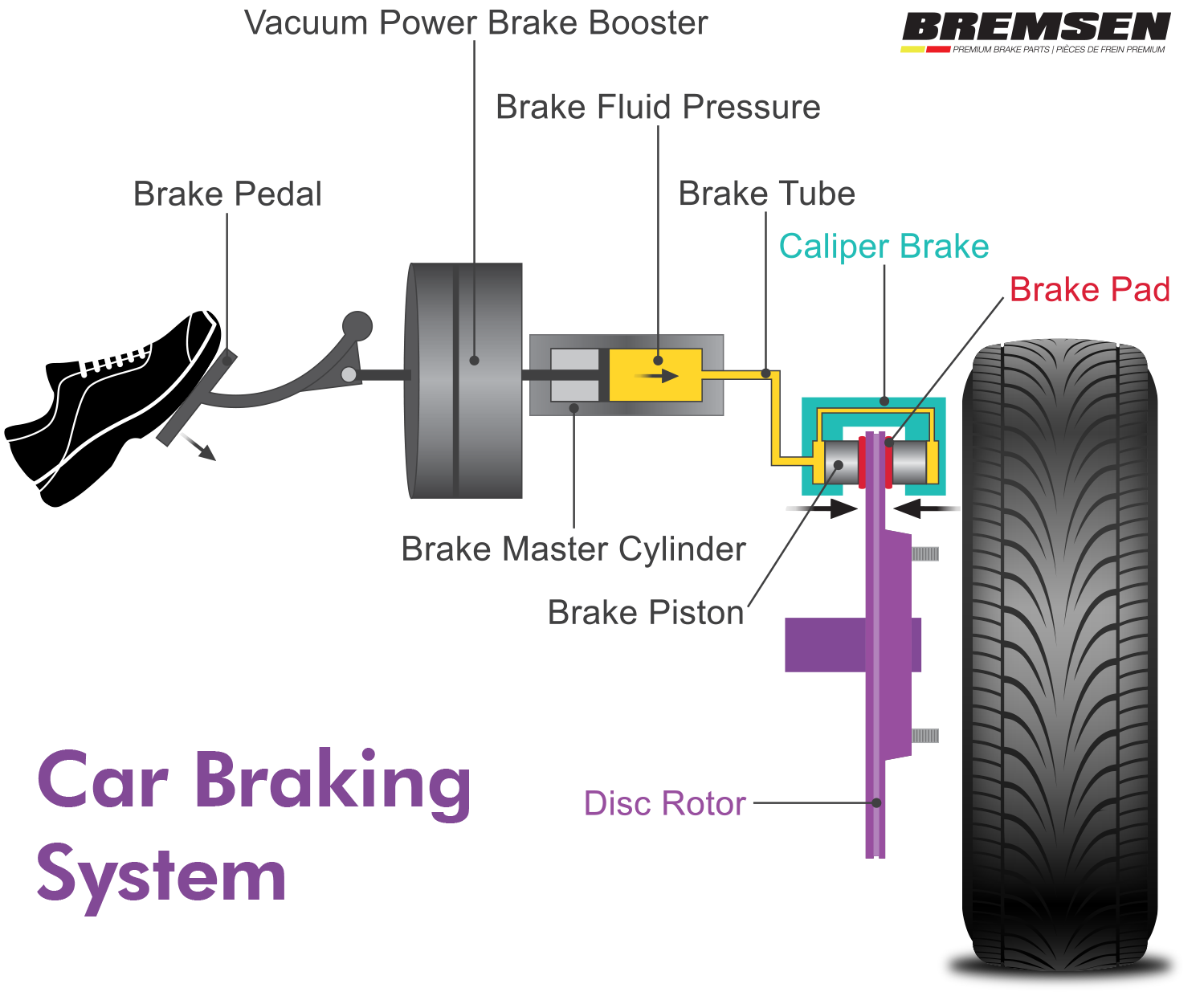

Brake calipers are essential components of a vehicle’s braking system. They play a crucial role in slowing down or stopping the vehicle when the brakes are applied. Understanding how brake calipers function can help you maintain your vehicle and ensure its safety on the road.

Operation:

- When you press the brake pedal, it activates a hydraulic system that sends brake fluid pressure to the calipers.

- The hydraulic pressure forces the pistons within the caliper to move outward, pressing the brake pads against the rotor.

- As the brake pads make contact with the spinning rotor, friction is generated, causing the rotor to slow down or stop rotating altogether.

- The kinetic energy of the rotating wheel is thus converted into heat energy through friction, dissipating into the surrounding air.

Types of Calipers:

- Fixed

- Floating

DIY Brake Job

Basic Components:

- Brake Caliper: This is a component that houses the brake pads and pistons. It’s typically made of metal and attaches to the suspension or wheel assembly.

- Brake Pads: These are friction materials that press against the brake rotor (or disc) to slow down or stop the vehicle.

- Pistons: Found within the caliper, these are responsible for pushing the brake pads against the rotor when hydraulic pressure is applied.

- Brake Fluid: Hydraulic fluid stored in the brake lines transmits force from the brake pedal to the calipers, enabling them to squeeze the brake pads against the rotor.

Tools Needed:

- Safety goggles

- Gloves

- Jack and jack stands (optional)

- Wrench set

- Brake cleaner

- Lubricating grease

- Rag or towel

Step-by-Step Guide:

- Understanding the Basics: Before delving into the workings of brake calipers, it’s essential to grasp the basics of how the braking system operates. When you press the brake pedal, hydraulic pressure is transmitted through brake lines to the calipers, which then squeeze the brake pads against the rotor, creating friction and slowing down the vehicle.

- Identifying Brake Calipers: Brake calipers are typically located near the wheels and are attached to the brake rotors. They come in various designs, including floating calipers and fixed calipers. Floating calipers move laterally to apply pressure to both sides of the rotor, while fixed calipers remain stationary and exert pressure evenly.

- Removing the Caliper: If you’re planning to inspect or replace your brake calipers, start by safely lifting your vehicle with a jack and securing it with jack stands. Once the wheel is removed, you’ll have access to the brake caliper. Depending on your vehicle, you may need to remove retaining bolts or clips to detach the caliper from the rotor.

- Exploring Internal Components: Inside the brake caliper, you’ll find pistons, brake pads, and seals. The pistons are responsible for pushing the brake pads against the rotor when hydraulic pressure is applied. Seals prevent brake fluid leaks and contamination, while the brake pads provide the friction necessary for stopping the vehicle.

- Understanding Piston Movement: When you press the brake pedal, hydraulic fluid forces the pistons within the caliper to move outward. This action causes the brake pads to clamp onto the rotor, generating friction and slowing down the vehicle. Upon releasing the brake pedal, the pistons retract, allowing the brake pads to release from the rotor.

- Maintenance and Care: Proper maintenance of brake calipers is crucial for ensuring optimal braking performance and safety. Periodically inspect the calipers for signs of wear, leaks, or corrosion. Clean the caliper and surrounding components with brake cleaner, and lubricate moving parts with high-temperature grease to prevent friction and ensure smooth operation.

- Reinstallation and Testing: After inspecting or replacing brake components, reassemble the caliper and wheel following the manufacturer’s guidelines. Double-check that all bolts and clips are securely fastened. Before hitting the road, pump the brake pedal several times to restore hydraulic pressure and ensure proper brake function. Finally, test the brakes in a safe environment to confirm they are operating correctly.

Did You Know?

Rear brake calipers on newer cars are often more sophisticated and have become more solicited for several reasons compared to vehicles from 20 years ago. Overall, the increasing solicitation of rear brake calipers on newer cars reflects advancements in automotive engineering and a continued commitment to improving vehicle safety, performance, and reliability.

Here are some key points explaining how Brake Calipers can play a significant role in ensuring driving safety and performance:

- Increased Emphasis on Safety: Safety standards and regulations have become more stringent over the years. Manufacturers are constantly striving to improve vehicle safety, and this includes enhancing braking systems. Upgrading rear brake calipers can contribute to better overall braking performance and stability, particularly in emergency braking situations

- Weight Distribution and Balance: Modern cars tend to have more balanced weight distribution between the front and rear axles for improved handling and stability. As a result, rear brakes play a more significant role in overall braking performance, necessitating more robust and efficient rear brake calipers.

- Electronic Stability Control (ESC): Many newer vehicles come equipped with ESC systems, which rely on individual wheel braking to help maintain vehicle stability during evasive maneuvers or slippery road conditions. Enhanced rear brake calipers can provide more precise control over rear wheel braking, contributing to the effectiveness of ESC systems.

- Increased Power and Performance: Today’s vehicles often have more powerful engines and higher performance capabilities compared to those from 20 years ago. As a result, they require more capable braking systems to safely bring them to a stop. Upgraded rear brake calipers can handle the increased braking forces generated by higher-performance vehicles

- Towing and Hauling Capacities: Modern vehicles, especially trucks and SUVs, are commonly used for towing trailers or hauling heavy loads. This places additional stress on the rear brakes, necessitating more durable and efficient rear brake calipers to handle the increased demands.

- Technological Advancements: Advancements in materials, manufacturing processes, and design technologies have enabled the development of more advanced and efficient brake calipers. Newer rear brake calipers may incorporate features such as larger piston sizes, improved heat dissipation, and better corrosion resistance, all of which contribute to enhanced braking performance and durability.

Conclusion

Brake calipers are integral to your vehicle’s braking system, and understanding how they work is essential for maintaining your vehicle’s safety and performance. By following this DIY guide, you can gain insight into the inner workings of brake calipers and ensure they function optimally for years to come.

Remember to always prioritize safety when working on your vehicle’s braking system and consult a professional if you encounter any difficulties or uncertainties.